✔ Competitive Pricing ✔ Quality Service ✔ Extensive Stock ✔ Experienced Staff

For Finding eXcellent Tools ..... look no further than Westcountry Machinery 4 Wood

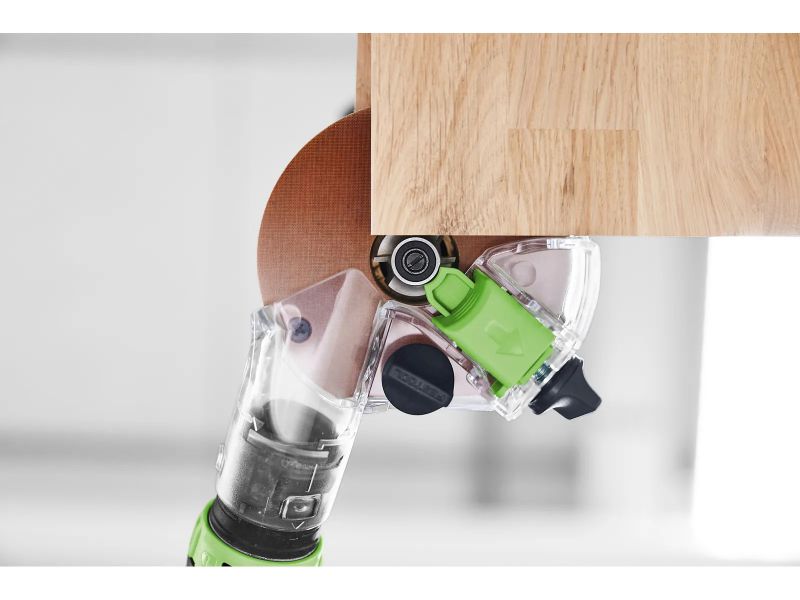

Festool 577985 Cordless Edge Router OFKC 500 R3 EB-Basic

Product Code: FES/577985

Brand: Festool

Several options are available for this product.

Please Choose Below

Festool 577985 Cordless Edge Router OFKC 500 R3 EB-Basic

Ergonomic, easy, quick. The cordless edge router for hassle-free jobs.

Key Features

A well-balanced centre of gravity and the sleek design make for tilt-proof routing. The cordless drive gives you greater agility and flexibility. Our cordless edge router delivers precise and clean routing results thanks to a depth adjustment that's accurate to 1/10 mm and a stable connection between the router and the drive. So, edge routing is super easy and straightforward, with no need for reworking.

- Mobile: Comfortably route edges without cables.

- Setting: Easy and accurate to 1/10 mm for adjusting the routing depth.

- No mess-ups: Perfect matching of all OFK 500 cutters (R1-6, chamfers, flush) for base runner drilling.

- Hard fibre base runner: Stops your workpiece getting damaged. Great glide and super scratch-resistant!

- Precision: Great run-out accuracy thanks to a solid link between the cutter and the drive.

- Cutter change: Quick and easy thanks to spindle stop.

- Handy: Slim build, lightweight and a well-balanced centre of gravity.

- Space to move: The ball bearing brake made from spring steel gives you more room to move when working without dust extraction.

- All-round support: The see-through dust extraction attachment with built-in ball bearing brake leads, slows down and sucks it all up.

- Convenient: The vacuum kicks off automatically thanks to the Bluetooth® battery pack.

- RPM control: Adjustable to your liking. Cuts down on scorch marks.

- Powerful: With a quiet, brushless EC-TEC motor.

- Long-lasting: Keeping an eye on the motor's temperature.

Items included

- HW R3-OFK 500 Z1 Roundover cutter

- Dust extraction attachment with a ball bearing brake

- Ball bearing guide KLS-D 15,8-OFK

- spring plate ball-bearing brake

- SYS3 M 187 Systainer³

- Battery and charger NOT included (find Festool battery packs and chargers here)

Applications

- Rounding and chamfering square timber, door frames and boards

- Flush trimming of edge veneer and strip material

Strengths and benefits

- More freedom thanks to the battery. Get ready for smooth workflows and easier handling of the machine without a messy tangle of cables. You can dive straight in with just a few settings.

- Easy and convenient. Lightweight, slim design for comfy working. Perfectly matched cutters for the base opening stop you from tipping over while routing into the material. This lets you route safely and quickly without having to redo anything.

- Precise Routing results. You can fine-tune the height precisely in 0.1 mm increments. Having the cutter mounted directly on the spindle boosts run-out accuracy and gives you a tidy finish. The flush ball bearing attachment on the cutter keeps the height low and lets you route in rebates or from the stack of panels.

- Shallow draft. The flush ball bearing mount on the cutter keeps the height down to just 12 mm and makes it easy to route in rebates or from a stack of panels.

- Spot on depth adjustment. The routing depth can be adjusted accurately to 1/10 mm. The lock prevents the router table from moving during operation and is easy to operate.

- Cutter replacement in seconds. The router can be changed quickly and easily thanks to the spindle stop.

- Spot on work. The clear dust extraction attachment makes sure that routing shavings are sucked up properly. The spring-loaded ball bearing brake stops scorch marks from appearing on the surface.

- Brushless EC-TEC motor. Efficiency, power, low noise and minimal vibrations: it’s all possible thanks to the brushless EC-TEC motor with built-in motor management.

- Lightweight and handy. The sleek design and tilted position of the battery pack give you a perfect centre of gravity whether you're using it horizontally or vertically.

- Excellent true-running precision. With the OFK 500 series, the cutter is mounted straight onto the spindle. That ensures top-notch run-out accuracy and the best quality work.

- Mobile thanks to the battery. The battery pack built in to the router, makes for easy edge routing without all the cable mess.

- Workpiece protected. The hard-wearing base runner stops nasty scratches or dents on the workpiece and gives you smooth sliding on any surface.

- No tipping over. Smaller hole diameter in the base plate and matching cutters for perfect milling results without tipping.

- More room to move about. Cheers to the spring plate on the ball bearing brake, you’ve got more space to move when working without dust extraction.

- Speed control adapted to the material. Thanks to the MMC electronics, you can quickly tweak the speed to match the material you're working with, and it stays constant even under load. Plus, the motor's temperature monitoring helps ensure it lasts a long time.

- Festool 18 V Bluetooth® battery packs. When you use Bluetooth® battery packs, you can easily combine cordless edge routers with the extractor's remote switch – machine on, extractor on.

- Link to the Festool App. By connecting to the Festool app, you can check out various machine data, like the last location. You can also quickly find the right accessories and handy tips. Plus, you can carry out software updates or create a repair order if you need a service.

Technical details

- Idle engine speed 10 000 - 25 000 min⁻¹

- Max. cutter diameter 28.00 mm

- Cutter stroke (fine-tuning) 10.00 mm

- Dust extraction connection diameter 27 mm

- Product weight without accessories 1.30 kg

- Transport weight incl. accessories 3.50 kg

- Drive type Battery

- Battery voltage (rated voltage) 18 V

Noise and vibration values

- Routing: Uncertainty (vibration) K 1.50 m/s²

- Routing: Uncertainty (noise) K 1.50 dB

- Routing: Total vibration average, Ah 2.50 m/s²

- Routing: Standards series EN 60745-2-17

- Routing: A-weighted sound pressure level, LpA 82.00 dB(A)

- Routing: A-weighted sound power level, LWA 90.00 dB(A)

Product Videos

Related Products & Accessories

01726 828 388

01726 828 388